- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

3-1/2", 7", 9-5/8", 13-3/8"

Xinlu

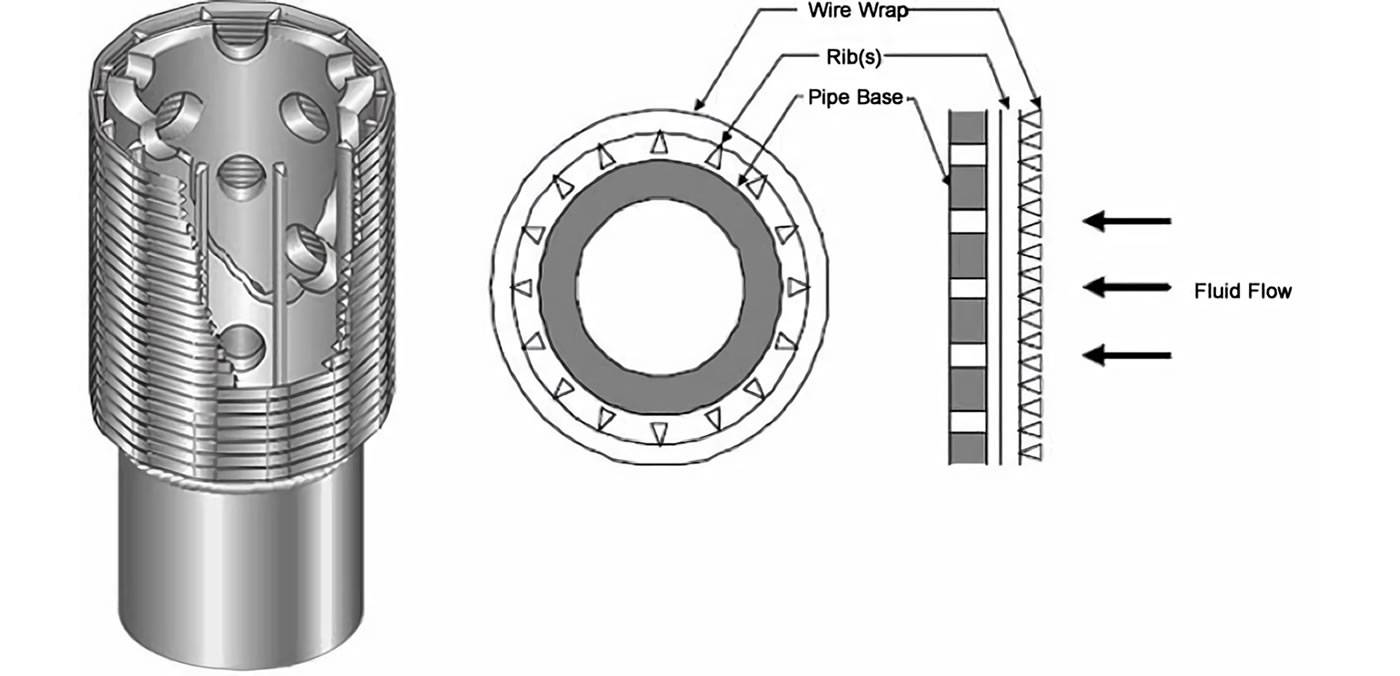

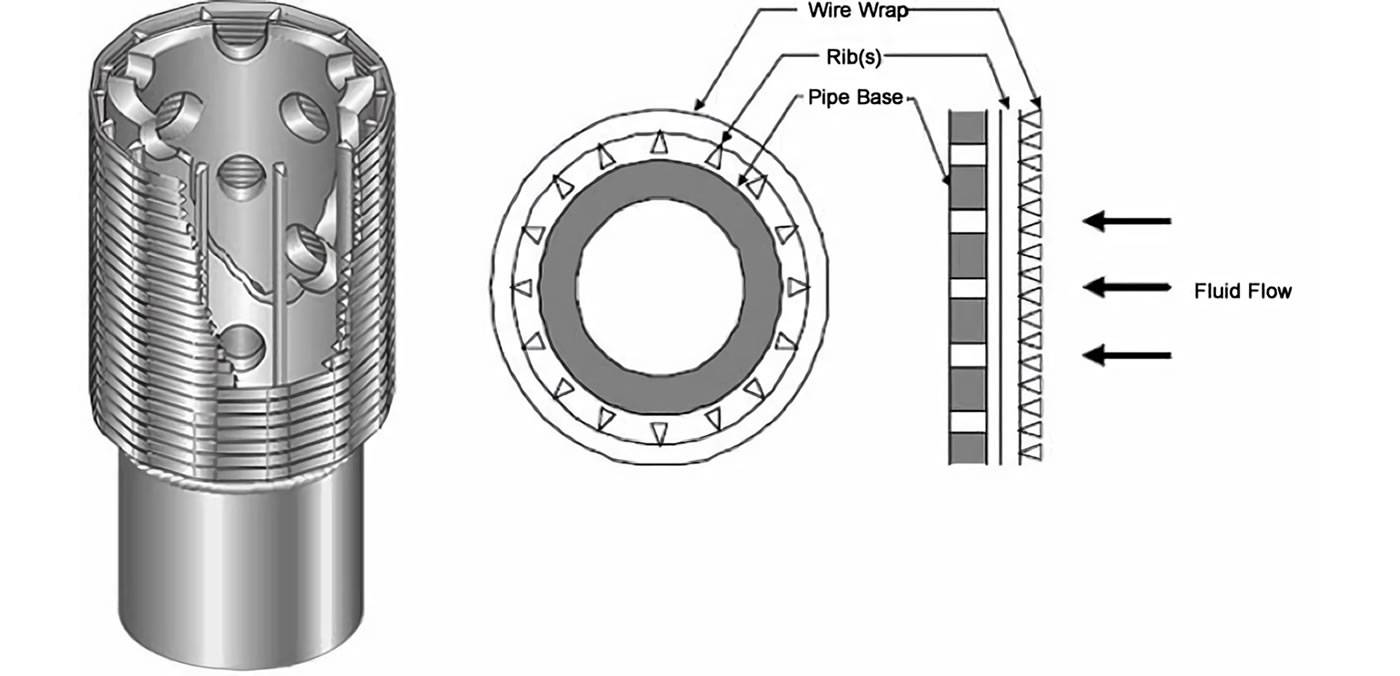

Anping County Xinlu Wire Mesh Products Co., Ltd introduces a range of Pipe Based Oil Well Screens, meticulously designed for resilience in high-pressure and high-temperature environments. Our screens are crafted with high-precision wedge wire wrapped around an API-compliant base pipe, offering superior structural integrity and performance.

Product Highlights:

Product Highlights:High-Precision Construction: Designed for severe conditions, including deviated wells.

Enhanced Support: Unique construction with a base pipe for extra support to the outer screen layer.

High Open Area: Utilizing smaller wedge wire for increased open area without compromising strength.

We offer a variety of oil well screen types, including but not limited to:

Wire-Wrapped Screens

Pipe Based Oil Well Screens

Bridge Slotted Screens

All-Welded Structure: For high mechanical strength.

Large Open Flow Area: Reducing pressure drop and increasing flow rate.

Self-Cleaning Function: Lowering the risk of plugging.

Various Connection Methods: Including thread, flange, and welding connections.

Materials: Stainless steelgrades 304, 304L, 316, 316L, galvanized low-carbon steel, or custom materials upon request.

Slot Openings: Range from 0.1mm to 15mm, tailored to specific well conditions.

Diameters: Available from 2 inches to 20", 50-500mm, accommodating various well sizes.

Length Options: Standard lengths of 2.9m, 5.85m, with a maximum length of 6.05m.

Connection Methods: Beveled, circumferential welded, and threaded connections for versatile installation.

Base Pipe Materials: API-compliant J55, K55, N80, stainless steel 304, low-carbon steel, or customized options.

Screen Diameter: Options from 1.5 inches (38mm) to 18 inches (457mm) to fit a broad range of well applications.

Wall Thickness: 3.5 to 8 mm.

Precise Particle Size Control: Ensuring optimal sand control.

High Strength and Durability: Suitable for harsh downhole environments.

Excellent Corrosion Resistance: Extending the service life of the screens.

Superior Erosion Resistance: Minimizing damage from fluid abrasion.

High Pressure Tolerance: Meeting the demands of high-pressure oil and gas wells.

Our Pipe Based Oil Well Screens are ideal for:

Vertical Wells

Horizontal Multi-lateral Deployments

High Load Bearing Applications

Environments with High Pressure and Temperature

Completion operations for vertical, directional, and horizontal wells.

Gravel packing and open-hole completions.

Sand control in oilfields, gas fields, and injection wells.

Geothermal wells and other specialized applications

At Anping County Xinlu Wire Mesh Products Co., Ltd, we are dedicated to delivering high-quality Pipe Based Oil Well Screens that exceed industry standards. Our commitment to quality is evident in every screen we produce.

Anping County Xinlu Wire Mesh Products Co., Ltd is committed to providing high-quality and high-performance pipe based oil well screens. Our products are manufactured in strict accordance with API standards, combining advanced production technology and extensive industry experience to ensure customer satisfaction.

Choose Anping County Xinlu Wire Mesh Products Co., Ltd for your Pipe Based Oil Well Screens and experience the reliability and efficiency that come with our precision-engineered solutions. Contact us today to discuss your well screen requirements.

Anping County Xinlu Wire Mesh Products Co., Ltd introduces a range of Pipe Based Oil Well Screens, meticulously designed for resilience in high-pressure and high-temperature environments. Our screens are crafted with high-precision wedge wire wrapped around an API-compliant base pipe, offering superior structural integrity and performance.

Product Highlights:

Product Highlights:High-Precision Construction: Designed for severe conditions, including deviated wells.

Enhanced Support: Unique construction with a base pipe for extra support to the outer screen layer.

High Open Area: Utilizing smaller wedge wire for increased open area without compromising strength.

We offer a variety of oil well screen types, including but not limited to:

Wire-Wrapped Screens

Pipe Based Oil Well Screens

Bridge Slotted Screens

All-Welded Structure: For high mechanical strength.

Large Open Flow Area: Reducing pressure drop and increasing flow rate.

Self-Cleaning Function: Lowering the risk of plugging.

Various Connection Methods: Including thread, flange, and welding connections.

Materials: Stainless steelgrades 304, 304L, 316, 316L, galvanized low-carbon steel, or custom materials upon request.

Slot Openings: Range from 0.1mm to 15mm, tailored to specific well conditions.

Diameters: Available from 2 inches to 20", 50-500mm, accommodating various well sizes.

Length Options: Standard lengths of 2.9m, 5.85m, with a maximum length of 6.05m.

Connection Methods: Beveled, circumferential welded, and threaded connections for versatile installation.

Base Pipe Materials: API-compliant J55, K55, N80, stainless steel 304, low-carbon steel, or customized options.

Screen Diameter: Options from 1.5 inches (38mm) to 18 inches (457mm) to fit a broad range of well applications.

Wall Thickness: 3.5 to 8 mm.

Precise Particle Size Control: Ensuring optimal sand control.

High Strength and Durability: Suitable for harsh downhole environments.

Excellent Corrosion Resistance: Extending the service life of the screens.

Superior Erosion Resistance: Minimizing damage from fluid abrasion.

High Pressure Tolerance: Meeting the demands of high-pressure oil and gas wells.

Our Pipe Based Oil Well Screens are ideal for:

Vertical Wells

Horizontal Multi-lateral Deployments

High Load Bearing Applications

Environments with High Pressure and Temperature

Completion operations for vertical, directional, and horizontal wells.

Gravel packing and open-hole completions.

Sand control in oilfields, gas fields, and injection wells.

Geothermal wells and other specialized applications

At Anping County Xinlu Wire Mesh Products Co., Ltd, we are dedicated to delivering high-quality Pipe Based Oil Well Screens that exceed industry standards. Our commitment to quality is evident in every screen we produce.

Anping County Xinlu Wire Mesh Products Co., Ltd is committed to providing high-quality and high-performance pipe based oil well screens. Our products are manufactured in strict accordance with API standards, combining advanced production technology and extensive industry experience to ensure customer satisfaction.

Choose Anping County Xinlu Wire Mesh Products Co., Ltd for your Pipe Based Oil Well Screens and experience the reliability and efficiency that come with our precision-engineered solutions. Contact us today to discuss your well screen requirements.

Specification of Pipe Based Oil Well Screens

Base Pipe | Screen Jacket | |||||||||

Nominal Diameter (in) | Outside Diameter (mm) | Weight lb/ft Wall Thickness (mm) | Hole diameter in | Hole Density | Hole Aprea In2/ft | OD of Screen Jacket (in) | Open area In2/ft Slot | |||

0.008” | 0.012” | 0.015” | 0.020” | |||||||

2-3/8 | 60.3 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

7 | 177.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

The above data is for reference only, actual information is subject to the drawings

Specification of Pipe Based Oil Well Screens

Base Pipe | Screen Jacket | |||||||||

Nominal Diameter (in) | Outside Diameter (mm) | Weight lb/ft Wall Thickness (mm) | Hole diameter in | Hole Density | Hole Aprea In2/ft | OD of Screen Jacket (in) | Open area In2/ft Slot | |||

0.008” | 0.012” | 0.015” | 0.020” | |||||||

2-3/8 | 60.3 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

7 | 177.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

The above data is for reference only, actual information is subject to the drawings